Thursday, November 21, 2024

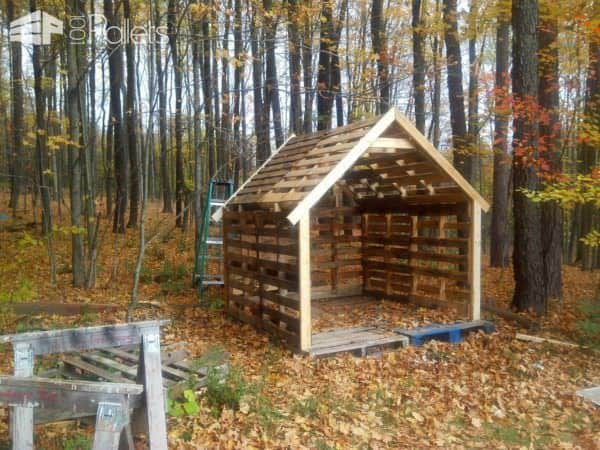

DIY Small Pallet Shed: Easy-to-Follow Instructions for Beginners

DIY Small Pallet Shed: Easy-to-Follow Instructions for Beginners

Hey there, fellow DIY enthusiasts! So you're thinking about building your own small pallet shed? That's awesome! It's a super rewarding project, and way cheaper than buying a pre-made one. Plus, you get to customize it exactly how you want it. This guide is designed to walk you through the entire process, even if you've never picked up a hammer before (though some basic DIY experience would be helpful). Let's get started!1. Planning and Gathering Supplies

Before you even touch a pallet, you need a plan. This isn't rocket science, but a little forethought will save you headaches down the line.1.1 Choosing Your Palettes

The foundation of your shed will be reclaimed pallets. Ideally, you want sturdy pallets made of good quality wood. Avoid pallets that are rotted, severely damaged, or showing signs of pest infestation. Check for the heat treatment stamp (HT or IPPC stamp) â€" this means the wood has been treated to prevent pest infestations. You'll probably need at least 6-8 pallets, depending on the size of shed you envision.

1.2 Designing Your Shed

Think about the dimensions. How much storage space do you need? Will you need a door? Windows? A simple rectangular design is easiest for beginners. Sketch out a quick plan on paper. Even a rough drawing is helpful to visualize your project. Consider the height you'll need to comfortably access the stored items.

1.3 Gathering Your Tools and Materials

Besides the pallets, you'll need a few essential tools and materials. This list might seem long, but trust me, you likely have some of these already!

- Measuring tape

- Hammer

- Screwdriver (or drill with screwdriver bits)

- Level

- Safety glasses

- Work gloves

- Wood screws (various lengths â€" get a mix of 2â€, 2.5â€, and 3â€)

- Crowbar or pallet pry bar (helpful for separating pallet components)

- Optional: Circular saw or hand saw (for cutting pallets down to size if necessary)

- Optional: Safety goggles (definitely recommended!)

- Optional: Power drill (makes things quicker and easier)

- Optional: Exterior wood sealant or paint (to protect your shed from the elements)

2. Preparing the Palettes

Now for the slightly more labor-intensive part. You’ll need to prepare your pallets for assembly.

2.1 Dismantling (or Not!)

This is a big decision. You can either use the pallets as-is or take them apart and reassemble them to create a cleaner look and stronger structure. If you dismantle them, be careful! Use your crowbar or pallet pry bar to carefully remove the nails and boards. Wear gloves and safety glasses. The wood might be splintery.

If you decide to use the pallets as-is, check for any loose boards or nails before you start building. Secure any loose components to prevent accidents later.

2.2 Cleaning the Palettes

Whether you dismantle or not, give your pallets a good clean. Use a wire brush to remove any loose debris, dirt, or stubborn bits of wood. A quick wipe down with a damp cloth will also help.

3. Building the Shed Frame

This is where things get exciting! You're going to assemble the basic framework of your shed.

3.1 Base Construction

Lay down your base pallets in the desired configuration. Ensure they are level and aligned with each other. You can use some landscape timbers or sturdy blocks to create a level surface if needed. Connect your base pallets using screws. Consider adding additional support beams to strengthen the base, especially if you're going to store heavy items.

3.2 Wall Construction

Start building your walls by attaching additional pallets vertically to the base. Use screws to secure the pallets to each other and to the base, ensuring everything is plumb (perfectly vertical) and level. It's helpful to use a level at this stage. Consider using additional support beams on the inside of the walls for extra strength. For a more weatherproof shed, you could add a layer of plywood to the walls before sealing it.

3.3 Roof Construction

The roof is usually the trickiest part. You can make a simple gabled roof using more pallets. You might need to cut some pallets to the correct angles to achieve the sloping roof effect. Secure the roof firmly to the walls using screws. Remember to ensure the roof is sloped to allow water to drain. A simple waterproof covering like roofing felt or heavy-duty plastic sheeting over your roof will enhance its durability.

3.4 Door Construction

Cut a doorway in one of the walls using a saw (circular saw is easier than a hand saw). If you are skilled with tools, create a simple frame for your door using leftover pallet wood or lumber. Use hinges to hang the door. A simple latch will suffice for the door securing mechanism.

4. Finishing Touches

Your shed is almost complete! Now for the finishing touches.

4.1 Sealing and Painting (Optional)

To protect your shed from the elements and give it a longer lifespan, consider applying a wood sealant or paint designed for exterior use. This will help to prevent rot and extend the life of your shed. Choose a color that complements your yard.

4.2 Adding a Floor (Optional)

If you desire a more finished look, adding a simple plywood floor will improve your shed's functionality. This is optional but highly recommended, especially if you're concerned about pests or moisture.

5. Safety First!

Throughout this entire process, please remember to prioritize safety. Wear safety glasses and work gloves at all times. Use caution when using power tools. If you're unsure about any part of the process, don't hesitate to ask for help or watch additional instructional videos.

Frequently Asked Questions

Q: How long does it take to build a pallet shed?

A: This depends on your experience level and the size and complexity of your shed. A simple shed could take a weekend, while a more complex one might take several days.

Q: How much does it cost to build a pallet shed?

A: The cost is mainly determined by the materials you need to purchase (screws, paint/sealant, plywood for the floor or walls). You can often find free pallets, significantly reducing costs. The total cost should be significantly lower than purchasing a pre-made shed.

Q: What kind of wood sealant should I use?

A: Opt for a high-quality exterior wood sealant that's designed to withstand weather conditions. Check with your local hardware store for recommendations.

Q: Can I use any type of pallet?

A: No, avoid pallets that are damaged, rotten, or show signs of insect infestation. Look for the heat treatment stamp to ensure the wood is pest-free.

Q: Do I need any specific skills?

A: Basic DIY skills are helpful, but this project is achievable for beginners. Watch some instructional videos beforehand and take your time.

And there you have it! Hopefully, this guide has given you the confidence to tackle your own DIY pallet shed project. Remember, take your time, enjoy the process, and don't be afraid to get a little creative. Happy building!

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.