Thursday, November 21, 2024

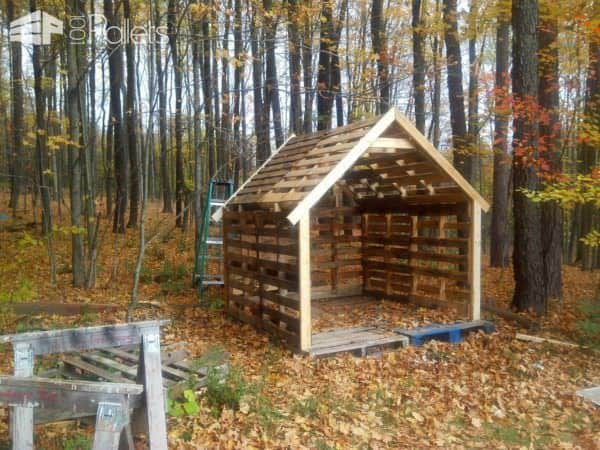

DIY Pallet Shed: Free Plans for Building a Shed with Recycled Pallets

DIY Pallet Shed: Free Plans for Building a Shed with Recycled Pallets

This comprehensive guide details the process of constructing a durable and aesthetically pleasing shed using reclaimed shipping pallets. This project offers a sustainable and cost-effective alternative to purchasing pre-fabricated sheds, while simultaneously providing a rewarding DIY experience. Detailed instructions, along with considerations for material selection, structural integrity, and finishing techniques, are provided to ensure a successful build.

I. Planning and Preparation: Laying the Foundation for Success

Before commencing construction, meticulous planning is crucial. This phase involves determining the shed's dimensions, location, and material requirements. Careful consideration of local building codes and regulations is also paramount.

A. Determining Shed Dimensions and Location

The first step involves determining the desired dimensions of your pallet shed. Consider the intended use of the shed to ascertain the necessary internal space. Factors such as storage capacity, accessibility, and the overall aesthetic impact on your property should be carefully weighed. Once the dimensions are finalized, select a suitable location that considers factors such as sunlight exposure, proximity to power sources (if needed), and ease of access.

B. Material Acquisition and Assessment

Sourcing reclaimed shipping pallets is a key element of this project. Inspect each pallet meticulously for signs of damage, rot, or infestation. Select only sound pallets free from structural defects. The number of pallets required will depend on the chosen dimensions of the shed. It's advisable to acquire more pallets than initially estimated to account for potential damage or unusable sections.

Beyond pallets, you will require additional materials including:

- Concrete or Gravel Base: For a stable foundation.

- Pressure-Treated Lumber: For framing and support structures.

- Screws and Nails: Of appropriate length and gauge.

- Weatherproofing Materials: Such as sealant, paint, or stain.

- Roofing Material: Consider asphalt shingles, metal sheeting, or recycled materials.

- Tools: Including hammers, saws, drills, levels, measuring tapes, and safety equipment.

C. Site Preparation and Foundation Construction

Once the materials are gathered, prepare the site by clearing any vegetation, debris, or uneven terrain. Construct a level foundation using either concrete or compacted gravel. The foundation's dimensions should precisely match the planned shed footprint. This step is vital for ensuring the stability and longevity of the structure.

II. Shed Construction: Assembling the Pallet Structure

With the foundation in place, the construction of the pallet structure can begin. This phase requires precision and attention to detail to ensure structural integrity and aesthetic appeal.

A. Pallet Disassembly and Preparation

Carefully disassemble the selected pallets. Remove any loose nails or staples. Inspect each plank for damage and discard any unusable components. Clean the planks thoroughly to remove dirt, debris, and any lingering pests. Consider sanding the surfaces for a smoother finish, if desired.

B. Frame Construction

Construct a robust frame using pressure-treated lumber. This frame will provide the underlying support for the pallet walls and roof. Ensure the frame is square and level using a level and measuring tape. The frame's dimensions should correspond to the overall dimensions of the shed. Secure the frame to the foundation using appropriate fasteners.

C. Wall Construction

Attach the prepared pallet planks to the frame to create the walls of the shed. Arrange the pallets to optimize aesthetics and structural integrity. Ensure that the pallets are tightly fitted together to prevent gaps and drafts. Use screws or nails to securely fasten the pallets to the frame. Consider using additional bracing for added stability.

D. Roof Construction

Construct the roof frame using pressure-treated lumber, mirroring the technique used for the main frame. Ensure the roof pitch is sufficient for water runoff. Cover the roof frame with your chosen roofing material, following the manufacturer's instructions. Secure the roofing material to prevent wind damage or leakage.

III. Finishing Touches: Enhancing Aesthetics and Functionality

Once the primary structure is complete, focus on enhancing the aesthetics and functionality of the shed.

A. Weatherproofing and Finishing

Apply a suitable weatherproofing treatment to protect the pallets from the elements. This might involve sealing, painting, or staining the pallets. Choose a product designed for exterior use and ensure complete coverage. This step is crucial for preserving the shed’s longevity and preventing rot or damage.

B. Door and Window Installation

Install a door and windows, if desired. Ensure that the door and window frames are securely attached to the pallet structure. Consider using pressure-treated lumber for these frames to enhance durability. Choose appropriate hardware for a secure and functional fit.

C. Interior Finishing

Consider adding interior shelving or storage solutions to maximize the shed's utility. This might involve constructing shelves from additional pallets or using other suitable materials. Ensure that any interior finishing is compatible with the overall aesthetics and functionality of the shed.

IV. Safety Precautions: Prioritizing Safety Throughout the Process

Throughout the construction process, maintaining safety should be paramount. Always wear appropriate safety equipment, including safety glasses, gloves, and hearing protection. Use caution when handling power tools and ensure that the work area is properly illuminated.

Proper disposal of waste materials is also crucial. Dispose of any debris or damaged pallets responsibly, adhering to local regulations and recycling guidelines. This contributes to the overall sustainability of the project.

Building a shed from recycled pallets is an environmentally responsible and rewarding endeavor. By carefully following these instructions and prioritizing safety, you can construct a durable and aesthetically pleasing shed that serves your needs for years to come. Remember to adjust these plans to suit your specific requirements and available resources. Enjoy the process and the satisfaction of creating something lasting from reclaimed materials.

DIY Small Pallet Shed: Easy-to-Follow Instructions for Beginners

DIY Small Pallet Shed: Easy-to-Follow Instructions for Beginners

Hey there, fellow DIY enthusiasts! So you're thinking about building your own small pallet shed? That's awesome! It's a super rewarding project, and way cheaper than buying a pre-made one. Plus, you get to customize it exactly how you want it. This guide is designed to walk you through the entire process, even if you've never picked up a hammer before (though some basic DIY experience would be helpful). Let's get started!1. Planning and Gathering Supplies

Before you even touch a pallet, you need a plan. This isn't rocket science, but a little forethought will save you headaches down the line.1.1 Choosing Your Palettes

The foundation of your shed will be reclaimed pallets. Ideally, you want sturdy pallets made of good quality wood. Avoid pallets that are rotted, severely damaged, or showing signs of pest infestation. Check for the heat treatment stamp (HT or IPPC stamp) â€" this means the wood has been treated to prevent pest infestations. You'll probably need at least 6-8 pallets, depending on the size of shed you envision.

1.2 Designing Your Shed

Think about the dimensions. How much storage space do you need? Will you need a door? Windows? A simple rectangular design is easiest for beginners. Sketch out a quick plan on paper. Even a rough drawing is helpful to visualize your project. Consider the height you'll need to comfortably access the stored items.

1.3 Gathering Your Tools and Materials

Besides the pallets, you'll need a few essential tools and materials. This list might seem long, but trust me, you likely have some of these already!

- Measuring tape

- Hammer

- Screwdriver (or drill with screwdriver bits)

- Level

- Safety glasses

- Work gloves

- Wood screws (various lengths â€" get a mix of 2â€, 2.5â€, and 3â€)

- Crowbar or pallet pry bar (helpful for separating pallet components)

- Optional: Circular saw or hand saw (for cutting pallets down to size if necessary)

- Optional: Safety goggles (definitely recommended!)

- Optional: Power drill (makes things quicker and easier)

- Optional: Exterior wood sealant or paint (to protect your shed from the elements)

2. Preparing the Palettes

Now for the slightly more labor-intensive part. You’ll need to prepare your pallets for assembly.

2.1 Dismantling (or Not!)

This is a big decision. You can either use the pallets as-is or take them apart and reassemble them to create a cleaner look and stronger structure. If you dismantle them, be careful! Use your crowbar or pallet pry bar to carefully remove the nails and boards. Wear gloves and safety glasses. The wood might be splintery.

If you decide to use the pallets as-is, check for any loose boards or nails before you start building. Secure any loose components to prevent accidents later.

2.2 Cleaning the Palettes

Whether you dismantle or not, give your pallets a good clean. Use a wire brush to remove any loose debris, dirt, or stubborn bits of wood. A quick wipe down with a damp cloth will also help.

3. Building the Shed Frame

This is where things get exciting! You're going to assemble the basic framework of your shed.

3.1 Base Construction

Lay down your base pallets in the desired configuration. Ensure they are level and aligned with each other. You can use some landscape timbers or sturdy blocks to create a level surface if needed. Connect your base pallets using screws. Consider adding additional support beams to strengthen the base, especially if you're going to store heavy items.

3.2 Wall Construction

Start building your walls by attaching additional pallets vertically to the base. Use screws to secure the pallets to each other and to the base, ensuring everything is plumb (perfectly vertical) and level. It's helpful to use a level at this stage. Consider using additional support beams on the inside of the walls for extra strength. For a more weatherproof shed, you could add a layer of plywood to the walls before sealing it.

3.3 Roof Construction

The roof is usually the trickiest part. You can make a simple gabled roof using more pallets. You might need to cut some pallets to the correct angles to achieve the sloping roof effect. Secure the roof firmly to the walls using screws. Remember to ensure the roof is sloped to allow water to drain. A simple waterproof covering like roofing felt or heavy-duty plastic sheeting over your roof will enhance its durability.

3.4 Door Construction

Cut a doorway in one of the walls using a saw (circular saw is easier than a hand saw). If you are skilled with tools, create a simple frame for your door using leftover pallet wood or lumber. Use hinges to hang the door. A simple latch will suffice for the door securing mechanism.

4. Finishing Touches

Your shed is almost complete! Now for the finishing touches.

4.1 Sealing and Painting (Optional)

To protect your shed from the elements and give it a longer lifespan, consider applying a wood sealant or paint designed for exterior use. This will help to prevent rot and extend the life of your shed. Choose a color that complements your yard.

4.2 Adding a Floor (Optional)

If you desire a more finished look, adding a simple plywood floor will improve your shed's functionality. This is optional but highly recommended, especially if you're concerned about pests or moisture.

5. Safety First!

Throughout this entire process, please remember to prioritize safety. Wear safety glasses and work gloves at all times. Use caution when using power tools. If you're unsure about any part of the process, don't hesitate to ask for help or watch additional instructional videos.

Frequently Asked Questions

Q: How long does it take to build a pallet shed?

A: This depends on your experience level and the size and complexity of your shed. A simple shed could take a weekend, while a more complex one might take several days.

Q: How much does it cost to build a pallet shed?

A: The cost is mainly determined by the materials you need to purchase (screws, paint/sealant, plywood for the floor or walls). You can often find free pallets, significantly reducing costs. The total cost should be significantly lower than purchasing a pre-made shed.

Q: What kind of wood sealant should I use?

A: Opt for a high-quality exterior wood sealant that's designed to withstand weather conditions. Check with your local hardware store for recommendations.

Q: Can I use any type of pallet?

A: No, avoid pallets that are damaged, rotten, or show signs of insect infestation. Look for the heat treatment stamp to ensure the wood is pest-free.

Q: Do I need any specific skills?

A: Basic DIY skills are helpful, but this project is achievable for beginners. Watch some instructional videos beforehand and take your time.

And there you have it! Hopefully, this guide has given you the confidence to tackle your own DIY pallet shed project. Remember, take your time, enjoy the process, and don't be afraid to get a little creative. Happy building!

DIY Lean-To Shed: Create a Shed for Your Garden Tools and Equipment

DIY Lean-To Shed: Create a Shed for Your Garden Tools and Equipment

Constructing a lean-to shed offers a practical and cost-effective solution for organizing garden tools and equipment. This comprehensive guide details the process of building a sturdy and functional lean-to shed, suitable for both novice and experienced DIY enthusiasts. The instructions provided emphasize safety precautions and best practices to ensure a successful project.

Phase 1: Planning and Preparation

Before commencing construction, meticulous planning is crucial for a successful project. This phase involves determining the shed’s dimensions, location, and material selection. Careful consideration of these factors will ensure the shed meets your specific needs and complies with local building regulations.

1.1 Determining Shed Dimensions and Location

The dimensions of your lean-to shed will depend on the amount of storage space required. Consider the size and quantity of tools and equipment you need to accommodate. A detailed inventory will help determine the necessary length and width. The height should allow for comfortable access and movement within the shed. The location should be carefully chosen, considering factors such as sunlight exposure, proximity to water sources (for potential drainage issues), and accessibility from your garden.

Important considerations:

- Ensure sufficient clearance from property lines and any existing structures.

- Assess the ground conditions to determine the need for ground preparation or foundation work.

- Check local building codes and obtain necessary permits if required.

1.2 Material Selection

Choosing appropriate materials is paramount for the longevity and durability of your lean-to shed. Pressure-treated lumber is recommended for its resistance to rot and insect infestation. Consider using durable roofing materials such as asphalt shingles or corrugated metal sheeting for weather protection. For the siding, you can choose from a variety of materials including wood, vinyl, or metal, based on your budget and aesthetic preferences. Hardware choices should prioritize strength and corrosion resistance.

Material List (example): This list is a starting point; quantities will vary based on your shed dimensions.

- Pressure-treated 4x4 posts for the frame

- Pressure-treated 2x4s for the framing

- Pressure-treated 1x6s for the siding

- Asphalt shingles or corrugated metal roofing

- Concrete blocks or a concrete slab for the base (optional)

- Nails, screws, and other fasteners

- Exterior-grade plywood for sheathing (optional, depending on siding choice)

- Weatherproof paint or sealant

1.3 Tool Acquisition and Safety Precautions

Gather the necessary tools before starting the project. This will ensure a smooth and efficient workflow. Essential tools include a measuring tape, level, saw (circular saw or hand saw), drill, hammer, shovel, post hole digger (if needed), safety glasses, work gloves, and hearing protection.

Safety is paramount:

- Always wear appropriate safety gear, including safety glasses and work gloves.

- Use caution when operating power tools. Ensure they are in good working order and follow all manufacturer instructions.

- Have a first-aid kit readily available.

- Never work alone on a construction project.

Phase 2: Construction

This phase involves the actual building of the lean-to shed. Follow these steps carefully and ensure accurate measurements throughout the process.

2.1 Foundation Preparation

A solid foundation is essential for a stable and long-lasting shed. For small lean-to sheds, a simple gravel base might suffice. However, for larger or heavier sheds, a concrete slab or concrete blocks provide greater stability. Level the ground thoroughly before laying the foundation.

2.2 Framing Construction

The framing forms the structural backbone of your lean-to shed. Begin by erecting the supporting posts at the desired intervals, ensuring they are plumb and level. Attach horizontal beams to the posts to create the framework for the walls and roof. Ensure all joints are securely fastened using appropriate nails or screws.

2.3 Roofing Installation

Roofing installation is a crucial step in protecting your shed from the elements. Begin by attaching the roofing sheathing (plywood or similar) to the roof framing. Then, install the chosen roofing material according to the manufacturer's instructions. Ensure proper overlap to prevent leaks. Consider using roofing felt or underlayment for added protection.

2.4 Siding Installation

Once the roof is complete, install the chosen siding material. This will protect the shed's interior from the elements and enhance its aesthetic appeal. Ensure that the siding is properly aligned and fastened securely. Leave appropriate gaps for ventilation.

Phase 3: Finishing Touches

After the main construction is complete, focus on the finishing touches to enhance the shed’s functionality and appearance.

3.1 Door and Window Installation

Install a door for convenient access to the shed’s interior. If desired, install windows for added light and ventilation. Ensure that all openings are properly sealed and weatherproofed.

3.2 Painting and Finishing

Apply a coat of weatherproof paint or sealant to protect the wood from the elements and enhance the shed's aesthetic appeal. Choose a color that complements your garden's landscape.

3.3 Interior Organization

Organize the interior of the shed to maximize storage space. Consider installing shelves, hooks, or pegboards to keep your tools and equipment neatly arranged. This will ensure easy accessibility and prevent damage.

Conclusion

Building a DIY lean-to shed is a rewarding project that provides valuable storage space for your garden tools and equipment. By carefully following these steps and prioritizing safety, you can create a durable and functional structure that enhances your gardening experience for years to come. Remember that accurate planning, careful execution, and attention to detail are key to achieving a successful outcome. Enjoy your newly constructed shed!

DIY Lean-To Shed Build: How to Make a Practical Outdoor Shed

DIY Lean-To Shed Build: A Comprehensive Guide to Constructing a Practical Outdoor Structure

Constructing a lean-to shed offers a rewarding DIY project, providing valuable additional storage space or a sheltered workshop area. This comprehensive guide outlines the planning, material selection, and construction phases, enabling even novice builders to successfully erect a functional and aesthetically pleasing lean-to shed.

Phase 1: Planning and Design

Before commencing construction, meticulous planning is paramount. This involves determining the shed's purpose, dimensions, location, and material choices.

Defining the Purpose and Dimensions

The intended use dictates the shed's size and features. A simple storage shed requires less space than a workshop requiring workbench integration or specialized shelving. Consider the volume of items to be stored and the necessary working space. Accurate measurements are crucial to prevent material waste and ensure a proper fit. Standard dimensions, such as 8ft x 10ft or 6ft x 8ft, offer a practical starting point, but customization is entirely feasible.

Choosing the Ideal Location

Site selection is crucial. Factors to consider include: proximity to power sources if electricity is required; accessibility for ease of material transport and future use; ground conditions, ensuring a level and stable base; sun exposure; and adherence to local building codes and regulations. Avoid placing the shed in low-lying areas prone to flooding or near overhanging trees that could pose structural damage risks.

Material Selection: A Balance of Durability and Cost

The choice of building materials significantly impacts the shed's longevity, cost, and aesthetic appeal. Pressure-treated lumber is a common and cost-effective choice for the frame, offering natural resistance to rot and insect infestation. Alternatively, cedar or redwood provide superior weather resistance but come at a higher price point. For roofing, consider asphalt shingles, corrugated metal sheets, or polycarbonate panels, each offering different levels of durability and cost-effectiveness. Always source materials from reputable suppliers to guarantee quality and consistency.

Obtaining Necessary Permits

Check with your local authorities to ascertain whether a building permit is required for your lean-to shed project. Building codes vary by region, and failing to obtain the necessary permits could lead to fines or even demolition orders. The application process typically involves submitting detailed plans, including dimensions, materials, and foundation details.

Phase 2: Foundation and Framing

A solid foundation is fundamental to a structurally sound lean-to shed. The framing provides the skeleton upon which the walls and roof will be constructed.

Preparing the Foundation

Several foundation options exist, ranging from a simple gravel base to more complex concrete slabs. For a lean-to shed, a gravel base or concrete footings are generally sufficient. Level the ground thoroughly, removing any vegetation or debris. For a gravel base, compact a layer of gravel at least 4 inches deep. For concrete footings, dig holes to accommodate the posts and pour concrete, ensuring they are level and plumb. Allow ample curing time before proceeding.

Framing the Structure

The framing process involves constructing the supporting framework for the walls and roof. Begin by erecting the main support posts, securing them to the foundation using concrete anchors or post base plates. Next, install the sill plate, a horizontal beam running along the base of the walls. Construct the wall frames by connecting vertical studs to the sill plate and header, ensuring proper spacing and alignment. For a lean-to shed, one side of the structure will usually lean against an existing wall or structure. Carefully measure and cut the lumber to ensure precise fit and stability. Use appropriate fasteners, such as galvanized nails or screws, to create a strong and secure frame.

Adding Wall Sheathing and Roofing

Once the frame is complete, install the wall sheathing. Plywood or OSB (Oriented Strand Board) are suitable options. Ensure proper alignment and secure fastening. For roofing, lay down roofing felt or underlayment as a moisture barrier before installing the chosen roofing material. Follow the manufacturer's instructions for proper installation, ensuring that the roof is sloped sufficiently to allow for effective water runoff. Consider adding gutters and downspouts to direct water away from the shed's foundation.

Phase 3: Finishing Touches and Safety Considerations

The final phase involves adding finishing touches, ensuring the shed is both aesthetically pleasing and safe.

Installing Doors and Windows

Install the chosen door and windows, ensuring they are properly sealed to prevent drafts and moisture intrusion. Use weather stripping to enhance insulation and reduce air leakage. Consider using durable, weather-resistant materials for the doors and windows. For added security, install sturdy locks.

Finishing the Exterior

Depending on the chosen materials, the exterior may require further treatment. Pressure-treated lumber typically requires no further treatment, but painting or staining will enhance its aesthetic appeal and provide additional protection. Other materials may require specific finishing techniques to maintain their durability and weather resistance.

Safety Precautions

Throughout the construction process, prioritize safety. Always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and work boots. Use caution when working with power tools, and follow all manufacturer's safety instructions. Ensure the work area is well-lit and free of hazards. When working at heights, utilize appropriate safety harnesses and scaffolding. Dispose of construction debris responsibly, complying with local regulations.

Conclusion

Building a lean-to shed is a fulfilling project that provides valuable outdoor storage or workspace. By following this comprehensive guide and prioritizing careful planning, quality materials, and safe construction practices, you can create a durable and functional structure that will serve your needs for years to come. Remember that adapting this guide to your specific needs and circumstances is key to a successful outcome. Consult additional resources and seek professional advice when needed.

Download Free Pallet Shed Plans PDF: Build Your Own Backyard Shed

Download Free Pallet Shed Plans PDF: Build Your Own Backyard Shed

The allure of a backyard shed is undeniable. It offers invaluable extra storage space, a dedicated workshop area, or even a charming retreat, all within the convenience of one's property. However, the cost of professionally built sheds can be prohibitive. A resourceful and cost-effective alternative involves constructing a shed using reclaimed pallets. This article provides a comprehensive guide to building your own backyard pallet shed, including detailed planning, material sourcing, construction techniques, and safety considerations. While free downloadable PDF plans are readily available online, this guide will delve deeper into the intricacies of the project, ensuring a successful and durable outcome.

Phase 1: Planning and Design

Before embarking on the construction, meticulous planning is paramount. This phase involves determining the shed's size, location, desired features, and necessary materials. Careful consideration at this stage will prevent costly errors and ensure a structurally sound and aesthetically pleasing result.

Determining Shed Dimensions and Location

The dimensions of your pallet shed will depend on your storage needs and available space. Consider the types and quantities of items you intend to store. Accurate measurements are crucial. Sketch a detailed plan, indicating the shed's length, width, and height. Choose a location that is level, accessible, and complies with local building regulations. Factors to consider include proximity to utilities, drainage, and sunlight exposure.

Choosing Pallet Types and Assessing Their Condition

The quality of the pallets significantly impacts the shed's durability. Select pallets constructed from strong, untreated wood. Avoid pallets showing significant signs of rot, insect infestation, or damage. Inspect each pallet carefully for loose nails, broken boards, or other structural weaknesses. Prioritize pallets of consistent dimensions for easier construction.

Essential Tools and Materials List

Assembling a comprehensive list of tools and materials is crucial to ensure a smooth construction process. The list should include:

- Pallets: The quantity will depend on the shed's size and design.

- Measuring tape and level: Essential for accurate measurements and ensuring a level foundation.

- Hammer and crowbar: For dismantling and assembling pallets.

- Screws and nails: Choose exterior-grade fasteners for durability.

- Drill and screwdriver bits: For efficient fastening.

- Saw: For cutting pallets to size.

- Safety glasses and gloves: Essential for protecting against injuries.

- Post-hole digger or shovel: For creating foundation supports (optional but recommended).

- Concrete mix (optional): For setting foundation supports.

- Wood preservative and sealant: To protect the wood from the elements.

- Roofing material: Tar paper, corrugated metal, or recycled materials are suitable options.

Phase 2: Construction Process

This phase involves the actual building of the shed. This is a hands-on process requiring careful attention to detail and adherence to safety protocols. The specific steps will vary depending on the chosen plan, but general principles remain consistent.

Foundation Preparation

While not strictly necessary for smaller sheds, a foundation provides stability and longevity. A simple approach involves setting concrete piers or using pressure-treated lumber as footings. Ensure the foundation is level before proceeding to the next steps.

Wall Construction

Begin by disassembling the pallets, removing any loose nails or damaged wood. Construct the walls using the reclaimed pallet wood, ensuring the structure is square and plumb. Use screws or nails to secure the pallets together. Consider adding vertical supports for added strength, particularly for taller sheds. Proper bracing is essential to prevent warping and maintain structural integrity.

Roof Construction

The roof design should complement the shed's size and style. A simple gable roof is a common and relatively easy-to-construct option. Ensure sufficient overhang to protect the walls from rain. Use strong, weather-resistant roofing material. Proper sealing around the roof edges is crucial to prevent water leakage.

Door and Window Installation (Optional)

If desired, incorporate a door and windows into the shed's design. Ensure the door is securely fastened and properly sealed to prevent drafts and unwanted entry. Windows can add natural light and ventilation. Use appropriate hardware and sealing materials.

Phase 3: Finishing Touches and Maintenance

Once the shed's structure is complete, apply a wood preservative and sealant to protect the wood from moisture damage and insect infestation. This will extend the shed's lifespan and enhance its aesthetic appeal. Consider adding a decorative element, such as paint or stain, to personalize the shed's appearance.

Regular Maintenance

Regular maintenance is essential to ensure the longevity of your pallet shed. Inspect the structure periodically for any signs of damage or deterioration. Address any issues promptly to prevent further problems. Re-apply sealant as needed to maintain protection against the elements.

Safety Considerations

Safety should be prioritized throughout the entire construction process. Always wear appropriate personal protective equipment (PPE), including safety glasses and gloves. Use caution when working with sharp tools and heavy materials. Ensure the work area is well-lit and free of obstructions. If unsure about any aspect of the construction, consult a qualified professional.

Building a pallet shed is a rewarding project that combines creativity, resourcefulness, and practical skills. By carefully following the planning stages, adhering to proper construction techniques, and prioritizing safety, you can create a durable and functional addition to your backyard. Remember to always consult local building codes and regulations before commencing any construction project.

DIY Pallet Shed: Practical and Eco-Friendly Building Tips

DIY Pallet Shed: Practical and Eco-Friendly Building Tips

Dreaming of a charming, functional shed without breaking the bank or harming the planet? Building a DIY pallet shed offers a fantastic solution. This eco-friendly project repurposes reclaimed wood, reducing waste and adding a rustic charm to your property. However, success hinges on careful planning and execution. This guide provides detailed steps and essential tips to ensure your pallet shed project is both structurally sound and aesthetically pleasing.

Sourcing and Assessing Your Pallets

The foundation of your shed rests on the quality of your pallets. Don't just grab any old pallet. Inspect each one thoroughly. Look for signs of rot, pest infestation (termites or woodworm), and significant damage. Prioritize heat-treated pallets marked with "HT" â€" these are safer and less likely to contain harmful chemicals or pests. Avoid pallets marked with "MB" (methyl bromide), as this fumigant is toxic. Aim for pallets of consistent size and build for easier construction. You'll likely need a significant number, so plan ahead and source them from reputable suppliers or businesses that are happy to donate used pallets.

Cleaning and Preparing the Pallets

Once you've collected your pallets, dedicate time to cleaning and preparing them. Remove any loose nails, staples, or debris using a hammer, crowbar, and pliers. Scrub the wood thoroughly with a stiff brush and water to remove dirt and grime. Let them dry completely in the sun before proceeding. Consider sanding rough edges and surfaces for a smoother finish and to remove any splinters. A pressure washer can significantly speed up the cleaning process. Finally, apply a wood preservative to protect against rot, insects, and weathering, ensuring your shed’s longevity.

Designing and Planning Your Pallet Shed

Before you start hammering, create a detailed plan. Sketch your shed's dimensions, including the height, width, and depth. Consider the storage needs you intend to meet. Will you store gardening tools, bikes, or larger equipment? This determines the internal space and overall size required. Factor in local building codes and regulations regarding shed size and placement on your property. A simple design is often easier to construct. You might want to consider adding features like a door, windows for ventilation, and a roof that effectively sheds water. A detailed blueprint will simplify the construction process significantly.

Choosing the Right Foundation

A sturdy foundation is paramount. Simply placing pallets directly on the ground leads to rot and instability. Consider these options:

Construction and Assembly

Assemble your pallet shed systematically. Begin by building the base frame using pressure-treated lumber or sturdy, reclaimed wood if you’ve chosen a wooden base. Then, carefully erect the walls using the pallets, ensuring they are securely fastened together using appropriate screws and strong wood glue. Check for plumbness regularly to prevent leaning walls. Construct the roof structure using sturdy beams and appropriate roofing material; consider asphalt shingles, corrugated metal, or recycled plastic sheets for an eco-friendly option. Finally, install the door(s) and any windows. Remember, precision and patience are key elements in this phase to create a durable and aesthetically pleasing shed.

Finishing Touches and Maintenance

Once the structural work is complete, add your finishing touches. Consider painting or staining the pallets to match your existing structures or to add a personal touch. This not only enhances the aesthetics but also offers further protection against the elements. You might even want to add some decorative elements like climbing plants to further blend your shed with the natural surroundings. Regular maintenance, including cleaning, inspecting for damage, and repainting/re-staining as needed, will significantly extend the lifespan of your DIY pallet shed.

How to Build a Pallet Shed with These Free PDF Plans

Building Your Dream Pallet Shed: A Step-by-Step Guide Using Free Plans

So, you've got your hands on some free pallet shed plans â€" fantastic! Building a shed from reclaimed pallets is a seriously rewarding project. It's eco-friendly, budget-friendly, and lets you unleash your inner DIY guru. This guide will walk you through the entire process, from prepping your materials to admiring your stunning new shed. We'll assume you've already got your plans â€" if not, a quick Google search for "free pallet shed plans PDF" will yield plenty of options. Remember to choose plans that match your skill level and desired shed size!

Getting Started: Preparation is Key

Before you even think about hammering a nail, thorough preparation is crucial. This phase sets the foundation for a smooth and successful build. Rushing this stage often leads to frustration and potentially, costly mistakes down the line.

Gathering Your Materials

Your free plans will specify the number and type of pallets you'll need. Don't skimp here! The structural integrity of your shed depends on the quality of your pallets. Look for pallets that are sturdy, free from rot, and have relatively straight boards. Avoid pallets that show significant signs of damage or pest infestation. You'll also need:

- Screws: Choose exterior-grade screws long enough to penetrate the wood adequately. A variety of lengths will be helpful.

- Hammer and/or Drill/Driver: A cordless drill with various bits will significantly speed up the process.

- Measuring Tape and Level: Accuracy is everything in construction.

- Saw: A circular saw is ideal, but a hand saw will do if that's what you've got.

- Safety Glasses and Gloves: Protect yourself from splinters and flying debris.

- Post Mix Concrete (if required): Some plans might call for concrete footings for added stability. Check your plans!

- Additional Lumber (possibly): Depending on the plan, you might need some extra lumber to fill gaps or reinforce certain areas. It’s always a good idea to have some extra wood on hand.

Preparing the Pallets

Pallet wood often has nails and other debris embedded in it. Safety first! Wear your gloves and safety glasses. Use a claw hammer or pry bar to remove any loose nails or protruding pieces of metal. Inspect each board carefully for rot, cracks, or insect damage. Replace any severely damaged boards with new lumber.

Consider cleaning the pallets. A pressure washer works wonders, but a good scrubbing with a stiff brush and soapy water will do the job. Let them dry completely before proceeding. You might also want to sand down any rough edges for a smoother finish.

Construction: Following Your Plans

This is where the fun begins! Carefully follow the instructions in your free plans. Take your time and don't rush. Each step builds upon the previous one, so accuracy is paramount. Here's a general overview:

Foundation (If Applicable)

If your plans call for a concrete base, this is your first step. Prepare the area, dig the holes, and pour the concrete according to the instructions. Let it cure completely before moving on. For simpler shed designs, you may be able to build directly on compacted earth or a gravel base. Always check your plans!

Framing the Walls and Roof

This usually involves assembling the pallet walls first, then attaching them to the base. Pay close attention to the plans regarding how the pallets are positioned and interconnected. Use plenty of screws to ensure a strong and stable structure. The roof framing follows a similar process, using the pallets to create the necessary slope for water runoff. Many plans offer detailed illustrations â€" make use of them!

Adding the Roof

Once the roof frame is complete, you'll likely need to add roofing material. This could be anything from tarps to corrugated metal sheets, or even more pallets! Consult your plans for specific recommendations. Ensure the roofing is securely fastened to prevent leaks and damage from wind.

Finishing Touches

After the main structure is complete, it's time for the finishing touches. This might involve adding doors, windows, or any other features specified in your plans. You might also choose to paint or stain your shed to protect the wood and enhance its appearance. Consider adding a lock for security.

Maintenance and Longevity

With proper care, your pallet shed can last for years. Regularly inspect the structure for any signs of damage or deterioration. Address any issues promptly to prevent further problems. A yearly coat of paint or sealant will significantly extend the life of your shed and protect it from the elements.

Remember that pallet wood is reclaimed, so it might not be as durable as new lumber. If you notice any signs of significant wear or damage, consider replacing or reinforcing those sections. A little preventative maintenance goes a long way.

Frequently Asked Questions

- Q: How long does it take to build a pallet shed? A: This depends on the size and complexity of the shed, as well as your experience level. Expect to spend several days to a couple of weeks, working in stages.

- Q: Are pallet sheds weatherproof? A: Not inherently. You'll need to treat the wood and apply a waterproof sealant or paint to protect it from the elements. Proper roofing is also crucial.

- Q: Can I use any type of pallet? A: No. Avoid pallets treated with chemicals (look for markings like "HT" for heat-treated) that could be harmful. Choose sturdy, undamaged pallets from reliable sources.

- Q: How much does it cost to build a pallet shed? A: The main cost is likely your time. The materials are often free or very inexpensive, making it a budget-friendly option compared to buying a pre-built shed.

- Q: What about permits? A: Check with your local authorities. Permits might be required depending on the size and location of your shed.

- Q: Can I customize the plans? A: Absolutely! Free plans are a great starting point. Feel free to adapt them to your specific needs and preferences, but always ensure structural integrity remains sound.

Building a pallet shed is a fantastic project that combines creativity, resourcefulness, and practical skills. Enjoy the process, and most importantly, be proud of your accomplishment!

Create Your Own Simple Pallet Shed: Simple Plans for Easy Building

Create Your Own Simple Pallet Shed: Simple Plans for Easy Building

Hey there, folks! So, you're thinking about building a shed, huh? Maybe you need extra storage, a workshop space, or just a charming little addition to your yard. But the thought of hiring a contractor or dealing with complicated blueprints is making your head spin? Don't worry, I get it. That's why I'm here to show you how to build a super simple, surprisingly sturdy shed using reclaimed pallets! It's cheaper, more eco-friendly, and way more satisfying than buying a pre-made one. Trust me, even if you’ve never picked up a hammer before, you can do this.Gathering Your Materials: The Pallet Powerhouse

The beauty of this project lies in its simplicity and resourcefulness. The star of the show? Reclaimed pallets! You can usually find these for free or very cheap from construction sites, behind businesses, or even on Craigslist. But here’s the thing: not all pallets are created equal.Choosing the Right Pallets

Look for pallets that are sturdy and relatively undamaged. Avoid those that are rotting, heavily splintered, or have loose boards. The most common size is 48" x 40", but you can adapt the plans to suit different sizes. Aim for pallets that have been heat-treated (look for the HT stamp) as they’re less likely to have pest infestations. Also, keep in mind that some pallets may be treated with chemicals, so wear gloves and a dust mask while handling them.Beyond Pallets: Your Supporting Cast Beyond the pallets, you’ll need a few other things: - Screws: Lots of them! Get a mix of lengths, from 2-inch to 4-inch, to accommodate different thicknesses of wood.

- Hammer or Drill/Driver: A drill with a screwdriver bit will save you a ton of time and effort.

- Measuring Tape and Level: Crucial for making sure everything is straight and square.

- Saw (Circular or Hand Saw): You might need to cut some pallets down to size or trim edges.

- Safety Glasses and Work Gloves: Protect your eyes and hands!

- Post Anchors and Concrete (optional): For added stability, especially in windy areas. These will secure the base of your shed to the ground.

- Roofing Material: Tarps, corrugated metal sheets, or even salvaged roofing materials can work. Consider the climate and your budget.

Building Your Pallet Shed: A Step-by-Step Guide

Let's get building! This is a basic design, so you can always customize it later to your liking. Step 1: Laying the Foundation

First, decide on the location and size of your shed. Clean the area and level the ground. You can create a simple base using more pallets, concrete pavers, or even a layer of compacted gravel. If you're aiming for extra stability, consider embedding post anchors in concrete at each corner of your shed before you build. This will create a very secure base! Step 2: Building the Walls

Start assembling the walls using your chosen pallets. You can either lay them horizontally or vertically, depending on your preference and the condition of the pallets. For a more solid structure, it’s recommended to attach the pallets together with screws, especially at the corners. Use your level frequently to ensure that your walls are plumb (perfectly vertical) and square (perfectly 90-degree corners). If necessary, cut pallets to fit. Step 3: Raising the Walls

Once the walls are built, carefully lift and position them into their places. Having a helper is a great idea at this stage! Use temporary supports to hold the walls in place until you can secure them. You can create corner supports using scrap wood, or by attaching pallets together. Remember to check that they are plumb and square again before moving to the next step. Step 4: Building the Roof

Your roof design will depend on your desired style and the available materials. A simple gable roof (triangular) is easy to build. You can make the rafters (the slanted roof supports) from scrap lumber or even from stronger pallets. Remember to consider the slope of your roof to ensure that water runs off effectively. Attach your chosen roofing material, ensuring it's securely fastened and waterproof. Step 5: Finishing Touches

Once the walls and roof are in place, it's time for the finishing touches. You can add a simple door using more pallets or a salvaged door. Consider adding a latch or lock for security. You may also want to paint or stain your shed to protect it from the elements and enhance its appearance. Tips and Tricks for Pallet Shed Success

- Inspect your pallets carefully: Remove any loose nails or staples before using them.

- Pre-drill holes: This prevents the wood from splitting when you screw it together.

- Use weatherproof screws: These will resist rust and corrosion.

- Consider adding insulation: This will help keep your shed cooler in summer and warmer in winter.

- Get creative with the design: Don't be afraid to personalize your shed!

Frequently Asked Questions (FAQs)

How long does it take to build a pallet shed?

The time it takes will depend on your experience and the complexity of your design. A simple shed can be built in a weekend, while a more elaborate design might take several days.

How much does it cost to build a pallet shed?

The cost is largely determined by the materials you need to buy beyond the pallets themselves. If you find free pallets, your cost will likely only be the screws, roofing, and any other supplementary materials you decide to use.

How durable is a pallet shed?

A well-built pallet shed can be surprisingly durable. The durability will depend on the quality of the pallets you use and how well you construct the shed. Proper treatment and maintenance will extend its lifespan significantly.

Do I need any special tools?

While a drill/driver is highly recommended, it is not essential. You can construct the shed using basic hand tools, but it will take longer. Safety glasses and work gloves are essential for every step of the process!

Can I use treated pallets?

While you can use treated pallets, be aware that some treatments contain chemicals that might be harmful. Always wear protective gear and research the type of treatment used on your pallets before you start building.

And there you have it! Building your own pallet shed is a rewarding and affordable project. Don’t be afraid to get creative and personalize it to fit your needs. Happy building!Saturday, November 16, 2024

12x20 Shed with Loft Plans: Downloadable PDF

12x20 Shed with Loft Plans: Your Dream Shed Awaits!

Hey there, fellow shed enthusiasts! Are you dreaming of a spacious, versatile shed? One that’s not just for storing garden tools, but a true extension of your living space? Then you've come to the right place! We're talking about a magnificent 12x20 shed with a loft â€" the ultimate in shed functionality and style. And the best part? I'm going to walk you through everything you need to know about finding or creating your own downloadable PDF plans.

Building your own shed can seem daunting, I get it. But with the right plans, it becomes a manageable and incredibly rewarding project. Forget flimsy, pre-fabricated sheds â€" let's build something truly special. Something you can be proud of for years to come. This guide will cover everything from choosing the right plans to understanding the construction process.

Why a 12x20 Shed with Loft?

A 12x20 shed offers a generous amount of space. But adding a loft? That's where the magic happens! You're essentially doubling your storage capacity. Think about it:

- Ground Floor Storage: Plenty of room for lawnmowers, bicycles, garden tools, outdoor furniture, and all those other bits and bobs that tend to accumulate.

- Loft Storage: The loft provides a perfect place for seasonal items, less frequently used equipment, holiday decorations, or even as a workshop space if you're so inclined.

- Versatility: Imagine transforming that loft into a cozy writing studio, a quiet meditation space, or even a guest room (with proper insulation and permits, of course!). The possibilities are endless.

- Increased Property Value: A well-built shed adds value to your property, particularly one as substantial and thoughtfully designed as a 12x20 with a loft.

Seriously, the benefits are numerous. It's an investment in your property and your lifestyle.

Finding Your Perfect 12x20 Shed with Loft Plans (Downloadable PDF)

Now, let's talk about getting your hands on those all-important plans. There are a few excellent ways to find downloadable PDF plans for your 12x20 shed with loft:

Online Retailers and Plan Providers

Many websites specialize in selling digital plans for various shed designs. Do some research, read reviews, and compare prices. Look for plans that offer detailed diagrams, materials lists, and step-by-step instructions. Make sure the plans are compatible with your local building codes â€" this is crucial.

DIY and Home Improvement Forums

Online forums and communities are treasure troves of information. You might find individuals who have shared their own shed plans or have links to resources. Be cautious, though â€" always verify the credibility of any plans you download from less established sources. It's worth the extra step to ensure the design is structurally sound.

Custom Design Services

If you're looking for something truly unique or have specific requirements, consider hiring a custom shed design service. They can work with you to create personalized plans that perfectly match your vision. This option is more expensive, but it provides a high level of customization.

What to Look For in Your Plans

No matter where you find your plans, make sure they include these essential elements:

- Detailed Drawings: Clear diagrams of the foundation, framing, roofing, and loft structure are essential.

- Complete Materials List: A comprehensive list of all lumber, fasteners, roofing materials, and other components you'll need.

- Step-by-Step Instructions: Easy-to-follow instructions, ideally with accompanying photos or illustrations.

- Building Codes Compliance: Ensure the plans comply with your local building codes and regulations.

- Foundation Details: Clear specifications for the type of foundation needed (concrete slab, piers, etc.).

- Loft Access Details: Specific plans for creating safe and easy access to the loft area (stairs, ladder).

Building Your 12x20 Shed with Loft: A Quick Overview

Once you have your plans, the construction process generally involves these key steps:

- Site Preparation: Clear the area, level the ground, and prepare the foundation.

- Foundation Construction: Build your chosen foundation according to the plans.

- Framing: Construct the walls, floor, and roof framing.

- Sheathing: Apply sheathing to the walls and roof.

- Roofing: Install the roofing material.

- Siding: Install the exterior siding.

- Loft Construction: Build the loft structure, including the flooring and supports.

- Interior Finishing: Finish the interior walls, add insulation (if desired), and paint or stain the interior.

Remember, safety is paramount! Always wear appropriate safety gear, use proper tools, and follow all instructions carefully. If you're unsure about any aspect of the construction, don't hesitate to seek professional advice.

Beyond the Basics: Adding Personal Touches

Your 12x20 shed with loft is a blank canvas! Consider these additions to personalize your space:

- Windows: Add windows for natural light and ventilation.

- Doors: Choose doors that suit your style and needs (double doors, single doors, etc.).

- Electricity: Run electricity to the shed for lighting and power tools (ensure you follow all safety regulations and obtain necessary permits).

- Insulation: Insulate the walls and roof for year-round comfort.

- Finishing Touches: Paint, stain, or add shelving and other organizational elements to complete the look.

Commonly Asked Questions

Here are some frequently asked questions about 12x20 sheds with lofts:

Q: Do I need a building permit?

A: This depends on your local regulations. It's crucial to check with your local authorities before starting construction.

Q: How much will it cost to build a 12x20 shed with a loft?

A: The cost varies widely depending on materials, labor, and your chosen features. Research material prices and consider if you'll hire help or do it yourself.

Q: How long will it take to build?

A: The timeframe depends on your experience, the complexity of the plans, and the time you dedicate to the project. Expect several weeks, potentially longer for a first-time builder.

Q: What kind of foundation do I need?

A: The best foundation depends on your soil conditions and local building codes. Your plans should specify the recommended foundation type.

Q: Can I use the loft for sleeping?

A: Possibly, but it will require careful planning, appropriate insulation, and likely adherence to stricter building codes. Consult with a building professional to ensure it meets safety standards.

I hope this guide helps you on your journey to building your dream 12x20 shed with loft! Happy building!

Monday, November 11, 2024

How to Build a Pole Barn with a High Clearance Design

Alright, so you're thinking about building a pole barn, huh? Maybe you need a big workshop, a spacious storage area, or you just want something that screams "I've got space!". And you're looking for that high clearance, that extra headroom to accommodate all your gear, your projects, maybe even a lift for your truck?

Well, let me tell you, building a high-clearance pole barn is a great way to get that extra space you need. It's not rocket science, but there are a few things you gotta keep in mind to make sure your project goes smoothly and you end up with a barn you're proud of.

First things first: What's the goal here?

Think about what you're going to use this pole barn for. Are you storing a boat, a motorhome, or a collection of classic cars? How tall do those things actually need to be? Don't just guesstimate â€" measure your stuff and add a good 2-3 feet for clearance. You'll be thanking yourself later.

Now, let's talk about the foundation. You've got options!

Concrete piers: This is the gold standard for pole barns. It's strong, durable, and will last you forever. Plus, you can build on pretty much any type of soil. The downside? It can get expensive.

Steel piers: These are a bit cheaper than concrete, but they're also a little less durable. They're a good choice if you're on a tight budget, but make sure you're using the right kind of steel for the climate you live in.

Pressure-treated wood posts: This is the most budget-friendly option, but it's also the least durable. If you're in a humid climate, wood can rot, so make sure you use pressure-treated lumber that's designed for above-ground use.

Once you've got your foundation sorted, it's time to start building the frame.

The poles that make up your barn's frame are usually made from steel, and they're super strong. You'll need to choose the right size and gauge for your project, and you'll need to make sure they're spaced correctly to support the weight of the roof and the walls. This is where you want to do your research and maybe even get a professional to help you out.

Next comes the roof.

A high-clearance pole barn usually means a high roof, which is a little trickier than a regular roof. You'll want to consider:

Roof pitch: A steeper pitch will help with snow load and drainage, but it will also be more expensive to build.

Roof material: Metal roofing is super durable and easy to maintain, but it can be noisy in the rain. You could also go with shingles, but they're not as long-lasting.

Gutters and downspouts: These are essential for directing water away from your barn and keeping the foundation dry.

Don't forget about the walls!

You've got a lot of options here too, from standard siding to metal panels to even wood boards. Just make sure you choose something that will hold up to the weather and looks good.

Now, the fun part: the interior!

This is where you can really let your imagination run wild. You can add windows, doors, and even a loft. Don't forget about insulation if you want to keep your barn comfortable year-round.

Let's talk about costs.

Building a high-clearance pole barn isn't cheap, but it's still usually more affordable than a traditional building. The cost will depend on a lot of factors, including:

Size: The bigger the barn, the more it will cost.

Materials: The type of materials you choose will also affect the price.

Labor: If you're doing the work yourself, you'll save money, but if you're hiring a contractor, it'll cost more.

Ready to get started?

Building a high-clearance pole barn is a big project, but it's definitely achievable, even for a first-timer. Here are a few things you can do to make sure your project goes smoothly:

Plan ahead: Draw up a detailed plan for your barn, including measurements, materials, and construction steps.

Get permits: Check with your local building department to see if you need any permits to build your barn.

Hire professionals for any jobs you're not comfortable doing yourself. You can save money by doing some of the work yourself, but there are certain tasks that are best left to the experts.

Take your time: Don't rush the process. Building a pole barn is a marathon, not a sprint.

With some planning and hard work, you can build a high-clearance pole barn that you'll be proud of for years to come.

Just a few more things to keep in mind:

Think about the future: Will you need to expand your barn in the future? If so, consider leaving room for that.

Don't forget the finishing touches: Add some landscaping around your barn to make it look its best.

Enjoy your new space! A high-clearance pole barn is a great way to get more space and enjoy your hobbies.

Building a pole barn is a fantastic way to get the space you need without breaking the bank. And who knows? You might even have some fun along the way!

How to Build a Pole Barn with a Custom Overhang and Roofline

Pole barns, with their distinctive simplicity and versatility, have become a popular choice for various structures, ranging from workshops and garages to agricultural buildings and recreational facilities. While the standard pole barn design offers a straightforward solution, customizing the overhang and roofline can significantly enhance functionality, aesthetics, and even improve energy efficiency. This guide will delve into the process of building a pole barn with a customized overhang and roofline, outlining essential considerations, step-by-step instructions, and expert tips for achieving a successful outcome.

1. Planning and Design:

a. Determine the Purpose and Size:

The first step is to define the intended use of your pole barn. Consider the activities you plan to undertake within the structure, the equipment or vehicles you intend to store, and the required space for comfortable movement. This will dictate the overall dimensions of the building, including its length, width, and height.

b. Design the Roofline:

The roofline is a key element in customizing the pole barn. Standard pole barns typically feature a gable roof, but you can explore various options like a gambrel roof, a shed roof, or even a hip roof. Each roof style presents unique benefits and drawbacks.

Gable Roof: This classic choice offers excellent drainage and simplicity of construction.

Gambrel Roof: This steeper roof maximizes usable attic space and provides increased storage potential.

Shed Roof: A single-slope roof ideal for covering a smaller area or creating a modern aesthetic.

Hip Roof: A multi-sloped roof offering enhanced structural stability and better wind resistance.

c. Define Overhang Dimensions:

The overhang extends beyond the walls of the structure, providing shade, protection from rain, and enhancing visual appeal. Calculate the desired overhang length based on your needs, considering factors like sun exposure, the size of your windows, and the desired aesthetic impact.

d. Incorporate Structural Integrity:

When designing a custom overhang and roofline, it's crucial to ensure structural integrity. Consult with a structural engineer to determine the necessary beam sizes, bracing requirements, and overall stability for your chosen design.

2. Site Preparation and Foundation:

a. Site Selection:

Choose a level site with adequate drainage and access for construction equipment. Consider the proximity of utilities and any potential obstructions.

b. Excavation and Foundation Preparation:

Excavate the foundation trenches according to your engineer's specifications. These trenches will house the concrete footings that will support the pole barn's structure. Install gravel fill for drainage and compaction.

c. Concrete Pouring:

Pour the concrete footings ensuring proper depth, width, and reinforcing steel placement. Allow the concrete to cure completely before proceeding.

3. Pole Installation and Framing:

a. Installing the Poles:

Erect the poles (typically made of treated lumber) in the pre-determined locations, ensuring they are plumb and level. Use concrete anchors or bolts to secure them to the footings.

b. Framing the Roof:

Once the poles are in place, construct the roof frame using beams, joists, and rafters. The framing structure should be designed to accommodate the chosen roofline and overhang.

c. Overhang Construction:

Attach the overhang joists to the main roof framing. Ensure these joists are properly braced and supported to withstand wind and snow loads.

4. Roof Sheathing and Roofing:

a. Sheathing Installation:

Attach the roof sheathing to the framing. This layer of plywood or OSB provides a solid base for the roofing material.

b. Roofing Installation:

Select a roofing material that suits your budget, aesthetics, and climate conditions. Popular options include asphalt shingles, metal roofing, or standing seam metal panels. Follow the manufacturer's instructions for proper installation.

c. Overhang Fascia and Soffit:

Install fascia boards to cover the ends of the overhang joists. Then, attach soffit boards to the underside of the overhang, creating a finished look and facilitating airflow.

5. Siding, Windows, and Doors:

a. Siding Installation:

Choose a siding material that complements the overall design and offers desired levels of insulation and maintenance. Common options include wood, vinyl, metal, and fiber cement.

b. Window and Door Installation:

Install windows and doors according to the chosen design and specifications. Ensure proper flashing and sealing to prevent leaks.

6. Finishing Touches:

a. Gutters and Downspouts:

Install gutters and downspouts to manage rainwater runoff, directing it away from the foundation.

b. Trim and Molding:

Add decorative trim and molding to enhance the aesthetic appeal of the structure.

c. Insulation and Finishing:

Insulate the walls and roof to improve energy efficiency and create a comfortable interior environment. Apply interior finishes like drywall, paint, or paneling.

7. Inspection and Final Touches:

a. Inspection:

Once construction is complete, have a professional building inspector assess the structure's compliance with local codes and regulations.

b. Finishing Touches:

Complete any remaining tasks like landscaping, driveway construction, and electrical and plumbing hookups.

Conclusion:

Building a pole barn with a customized overhang and roofline offers a unique blend of practicality and aesthetics. By following these steps and collaborating with a qualified engineer and builder, you can successfully construct a durable and attractive structure that perfectly suits your specific needs. Remember to prioritize safety, quality materials, and meticulous attention to detail throughout the process. This ensures that your pole barn will stand as a testament to your vision for years to come.

How to Build a Pole Barn with Minimal Tools and Equipment

Alright, you're ready to build a pole barn. Maybe you're tired of the overflowing garage, dreaming of a workshop, or just need a place to store your boat. But the thought of buying a ton of tools and equipment makes your wallet cringe. Don't worry, friend! You can build a solid, sturdy pole barn with just a handful of essential tools and a little elbow grease.

Let's Talk Tools:

The Powerhouse: You'll need a drill with a good set of drill bits. You'll be drilling into concrete, wood, and maybe even metal, so make sure you have a variety of bit sizes.

The Muscle: A good old-fashioned hammer is your best friend. You'll be pounding nails, securing things, and generally giving everything a good "tap."

The Cutters: A handsaw is your go-to for cutting lumber. A circular saw is helpful, but not absolutely necessary. You can get away with a handsaw and a good, sharp blade.

The Leveler: A level is crucial for, well, leveling everything. You don't want a crooked roof, do you?

The Measurer: A tape measure is indispensable. You'll be measuring everything from lumber to concrete footings. Get one that's at least 25 feet long.

The Tightener: A socket wrench set will come in handy for fastening bolts and nuts.

The Helpers: Don't forget the indispensable tools - a pry bar, a crowbar, and a couple of sturdy work gloves.

Planning Your Project:

The Blueprint: Before you even think about breaking ground, you need a plan. There are online resources and even software programs that can help you design your pole barn. Decide on the size, height, and layout.

The Foundation: Your pole barn needs a strong foundation. Concrete piers are a common and cost-effective choice. You can rent a concrete mixer or even hire a professional to pour them.

The Lumber: Once you have your foundation, you'll need to choose your lumber. Pressure-treated lumber is ideal for the posts and beams, as it's resistant to rot and insects.

The Roof: Decide on your roofing material - metal, shingles, or even a green roof. Each option has its pros and cons, so research what works best for your climate and budget.

The Extras: Do you want to add a garage door? Windows? Consider these elements early in your planning.

The Build:

The Base: Set your poles in the concrete piers, making sure they're perfectly plumb. You can use temporary bracing to hold them in place while the concrete cures.

The Beams: Once your poles are secure, you can install the beams that will support the roof. Use bolts and washers for a strong connection.

The Sheathing: Next, you'll attach sheathing boards to the beams, creating a solid base for your roof.

The Roof: Install the roof joists, and then add your chosen roofing material.

The Walls: If you're adding walls, you can use pre-made wall panels or build them yourself with studs and plywood.

The Finishes: Once the structure is up, you can add the finishing touches like siding, windows, and doors.

Tips for Success:

Get Help: Building a pole barn is a big project, so don't be afraid to enlist help from friends or family.

Take Your Time: Rushing can lead to mistakes, so take your time, double-check your measurements, and make sure you're happy with each step.

Stay Organized: Keep your tools and materials organized. It's easier to find what you need and prevents accidents.

Don't Be Afraid to Ask for Help: If you're unsure about something, don't hesitate to ask for help from a more experienced builder. There are plenty of resources available online and at your local hardware store.

The Reward:

Building a pole barn can be a challenging but rewarding experience. You'll gain a sense of accomplishment knowing you built something with your own hands, and you'll have a space that perfectly suits your needs. So, gather your tools, put on your work gloves, and get ready to build!

How to build a diy garden shed for all your yard tools and equipment

Alright, folks, let's talk sheds! You know that feeling, right? You're knee-deep in gardening, and you need your clippers...but where are they? Buried under a pile of potting soil? Lost in the depths of the garage? No worries, my friends, because building a DIY garden shed is about to solve all your storage woes and become your new favorite weekend project.

Let's Get Practical:

First things first, we need a plan. Don't jump in headfirst! Think about what you want this shed to be:

Size: How much stuff do you need to store? Don't go too small, but also be realistic about how much space you actually have.

Style: Do you want a classic A-frame, a sleek modern design, or something whimsical? The internet is your oyster!

Materials: Wood? Metal? Recycled materials? This depends on your budget and the style you're going for.

Time to Go Shopping!

Now comes the fun part - gathering your supplies. Here's a basic list:

Foundation: Concrete blocks, treated lumber, or even pavers can create a stable base.

Framing: Choose pressure-treated lumber for the floor and walls to resist moisture.

Sheathing: Plywood or OSB will provide strength and a smooth surface for siding.

Siding: Wood, metal, or even vinyl - the choice is yours!

Roofing: Shingles, metal, or even corrugated plastic - pick something that suits your style and budget.

Doors and Windows: Consider a single door for easy access, or go with double doors for larger items. Windows add natural light and ventilation.

Hardware: Screws, nails, hinges, handles, locks - the list goes on!

Building Your Shed: Let's Get Down to Business

1. Laying the Foundation:

Level out the area you've chosen for your shed. This is key for a stable structure!

Set your concrete blocks or pavers on a bed of gravel for drainage.

Anchor them together with concrete or masonry adhesive.

Double-check that your foundation is level before moving on.

2. Building the Floor:

Construct a frame of treated lumber for your floor. This will provide support for your sheathing.

Attach your plywood or OSB to the floor frame using screws or nails.

Consider adding a layer of flooring over the sheathing for a finished look.

3. Erecting the Walls:

Cut and assemble your wall frames. This is where you'll need those carpentry skills!

Sheathe the walls with plywood or OSB, attaching it to the framing with screws or nails.

Install any window or door openings at this stage.

4. Roofing Time:

Create a roof frame using lumber. This will determine the style of your shed's roof.

Sheathe the roof with plywood or OSB.

Add a layer of felt paper under your shingles for extra weatherproofing.

Install your chosen roofing material, whether it's shingles, metal, or something else entirely.

5. Finishing Touches:

Add siding to your shed, attaching it to the sheathing.

Install doors and windows, making sure to seal any gaps.

Paint or stain your shed to your liking.

Add any finishing touches, like trim, shelves, or hooks for extra organization.

Safety First!

Remember, safety is paramount. Always wear safety glasses, gloves, and appropriate footwear when working with power tools. Follow instructions carefully, and don't hesitate to ask for help if you need it.

The Reward:

The satisfaction of building your own garden shed is truly something special. You'll have a place to store your tools, equipment, and maybe even some gardening supplies. Plus, you'll have the pride of knowing you created something beautiful and functional with your own two hands.

Go Beyond the Basics:

Want to take your shed to the next level? Here are some ideas:

Electricity: Add a light or an outlet for power tools.

Heating and Cooling: Install a small heater or fan for year-round comfort.

Ventilation: Add vents to the roof or walls to improve air circulation.

Shelves and Storage: Build shelves or add hooks for easy organization.

From Project to Paradise:

Building a DIY garden shed isn't just about storage; it's about creating a haven for your green thumb. You'll have a dedicated space for your gardening tools, a place to pot plants, and a refuge to enjoy the beauty of your backyard. So, what are you waiting for? Get those tools ready and let's build a shed!

Sunday, November 10, 2024

Essential tools for building a 10x12 storage shed

Alright, you're ready to build a 10x12 storage shed, huh? That's awesome! It's a great way to get organized and reclaim some space around your house. But before you start nailing together boards, you gotta make sure you've got the right tools.

Let's break it down, tool by tool, so you're ready to conquer this project!

The Power Tools: Your Workhorse Friends

Circular Saw: This bad boy is gonna be your best friend for cutting lumber. You'll use it to cut the framing lumber to size, rip boards to specific widths, and trim the shed's roof and walls. A good circular saw with a sharp blade will make your life a whole lot easier.

Cordless Drill/Driver: You'll be using this all the time! It's not just for drilling holes, but also for driving in screws. Look for a drill with a good battery life and a powerful motor.

Impact Driver: This is a game-changer for driving screws into tough wood. It'll make the job quicker and easier, and you'll have less chance of stripping screws.

Jig Saw: For cutting curved or intricate shapes in your shed's trim, this is your go-to. You'll use it to cut around windows or to add decorative touches.

Finish Nailer: This tool will make attaching siding, trim, and other finishing details a breeze. It's quiet, precise, and will give you a professional-looking finish.

Reciprocating Saw (Sawzall): This tool is excellent for cutting through thick materials, like framing lumber, and for demolition if you need to remove any parts.

The Hand Tools: Your Faithful Sidekicks

Hammer: A good hammer is essential for driving nails, knocking down materials, and general construction tasks. Choose a hammer with a comfortable grip and a head that feels right for you.

Measuring Tape: You can't build anything straight without a measuring tape. Get a 25' tape measure, so you have plenty of reach for the shed's dimensions.

Level: A level is crucial for ensuring that your walls and roof are straight and plumb. You'll use it constantly throughout the build. Get a 4-foot level for best results.

Speed Square: This tool helps you make perfect 90-degree cuts and mark angles. It's a real lifesaver when building a shed.

Pencil: You'll need a pencil to mark your cuts and make your measurements.