HUG

Thursday, November 21, 2024

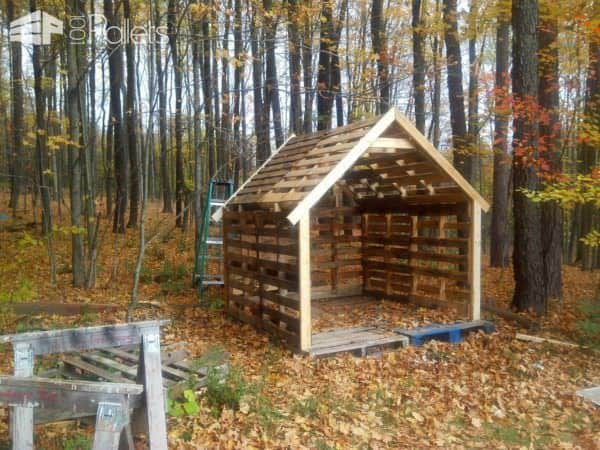

DIY Pallet Shed: Free Plans for Building a Shed with Recycled Pallets

DIY Pallet Shed: Free Plans for Building a Shed with Recycled Pallets This comprehensive guide details the process of constructing a durable and aesthetically pleasing shed using reclaimed shipping pallets. This project offers a sustainable and cost-effective alternative to purchasing pre-fabricated sheds, while simultaneously providing a rewarding DIY experience. Detailed instructions, along with considerations for material selection, structural [...]

DIY Small Pallet Shed: Easy-to-Follow Instructions for Beginners

DIY Small Pallet Shed: Easy-to-Follow Instructions for Beginners Hey there, fellow DIY enthusiasts! So you're thinking about building your own small pallet shed? That's awesome! It's a super rewarding project, and way cheaper than buying a pre-made one. Plus, you get to customize it exactly how you want it. This guide is designed to walk you through the entire process, even if you've never picked up a hammer before (though some basic DIY experience [...]

DIY Lean-To Shed: Create a Shed for Your Garden Tools and Equipment

DIY Lean-To Shed: Create a Shed for Your Garden Tools and Equipment Constructing a lean-to shed offers a practical and cost-effective solution for organizing garden tools and equipment. This comprehensive guide details the process of building a sturdy and functional lean-to shed, suitable for both novice and experienced DIY enthusiasts. The instructions provided emphasize safety precautions and best practices to ensure a successful project. [...]

DIY Lean-To Shed Build: How to Make a Practical Outdoor Shed

DIY Lean-To Shed Build: A Comprehensive Guide to Constructing a Practical Outdoor Structure Constructing a lean-to shed offers a rewarding DIY project, providing valuable additional storage space or a sheltered workshop area. This comprehensive guide outlines the planning, material selection, and construction phases, enabling even novice builders to successfully erect a functional and aesthetically pleasing lean-to shed. Phase 1: Planning and [...]

Download Free Pallet Shed Plans PDF: Build Your Own Backyard Shed

Download Free Pallet Shed Plans PDF: Build Your Own Backyard Shed The allure of a backyard shed is undeniable. It offers invaluable extra storage space, a dedicated workshop area, or even a charming retreat, all within the convenience of one's property. However, the cost of professionally built sheds can be prohibitive. A resourceful and cost-effective alternative involves constructing a shed using reclaimed pallets. This article provides a [...]

DIY Pallet Shed: Practical and Eco-Friendly Building Tips

DIY Pallet Shed: Practical and Eco-Friendly Building Tips Dreaming of a charming, functional shed without breaking the bank or harming the planet? Building a DIY pallet shed offers a fantastic solution. This eco-friendly project repurposes reclaimed wood, reducing waste and adding a rustic charm to your property. However, success hinges on careful planning and execution. This guide provides detailed steps and essential tips to ensure your pallet [...]

How to Build a Pallet Shed with These Free PDF Plans

Building Your Dream Pallet Shed: A Step-by-Step Guide Using Free Plans So, you've got your hands on some free pallet shed plans â€" fantastic! Building a shed from reclaimed pallets is a seriously rewarding project. It's eco-friendly, budget-friendly, and lets you unleash your inner DIY guru. This guide will walk you through the entire process, from prepping your materials to admiring your stunning new shed. We'll assume you've already got your [...]

Subscribe to:

Posts (Atom)